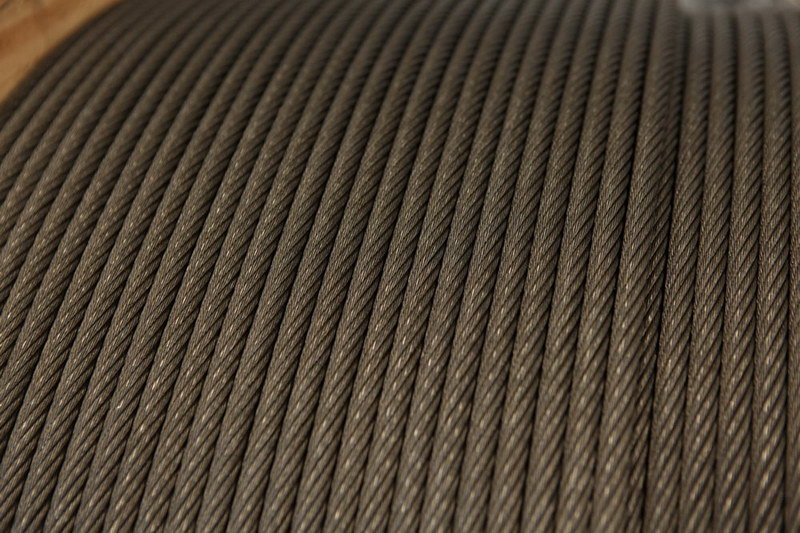

Steel Wire Rope 6*7+IWR

Steel Wire Rope 6*7+IWR

Additional Info

Diameter Range of rope: 6 mm -72 mm

Diameter Range of the strand: 8mm~65mm

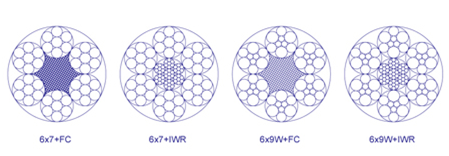

Structure: 6×9W+FC; 6×9W+IWR; 6×7+FC; 6×7+IWS; 6×7+IWR; 6×9W+FC; 6×9W+IWR

Surface Finish: Hot Dipped Galvanizing; Black; Phosphated

Standard: ASTM; BS; JIS; KS etc

Application: inclined shaft lifting (winch), belt conveyer, ropeway, pulling of suspension bridge on the vessel (Steel Cored)

Structure Photo

Breaking Load (KN)

| GB/T8918 | EN 12385-4 | |||||

| Diameter | Min. Breaking Load (kN) | Approx. | Min. Breaking Load(kN) | Approx. | ||

| (mm) | Weight | Weight | ||||

| 1670 N/mm2 | 1770 N/mm2 | (Kg/100m) | 1670 N/mm2 | 1770 N/mm2 | (Kg/100m) | |

| 2 | 2.21 | 2.35 | 1.4 | 2.22 | 2.35 | 1.38 |

| 3 | 4.98 | 5.28 | 3.16 | 4.99 | 5.29 | 3.11 |

| 4 | 8.87 | 9.4 | 5.62 | 8.87 | 9.4 | 5.52 |

| 5 | 13.8 | 14.6 | 8.77 | 13.9 | 14.7 | 8.63 |

| 6 | 19.9 | 21.1 | 12.6 | 20 | 21.2 | 12.4 |

| 7 | 27.1 | 28.7 | 17.2 | 27.1 | 28.8 | 16.9 |

| 8 | 35.4 | 37.6 | 22.5 | 35.5 | 37.6 | 22.1 |

| 9 | 44.9 | 47.5 | 28.4 | 44.9 | 47.6 | 27.9 |

| 10 | 55.4 | 58.7 | 35.1 | 55.4 | 58.8 | 34.5 |

| 11 | 67 | 71.1 | 42.5 | 67.1 | 71.1 | 41.7 |

| 12 | 79.8 | 84.6 | 50.5 | 79.8 | 84.6 | 49.7 |

| 13 | 93.7 | 99.3 | 59.3 | 93.7 | 99.3 | 58.3 |

| 14 | 108 | 115 | 68.8 | 109 | 115 | 67.6 |

| 16 | 141 | 150 | 89.9 | 142 | 150 | 88.3 |

| 18 | 179 | 190 | 114 | 180 | 190 | 112 |

| 20 | 221 | 235 | 140 | 222 | 235 | 138 |

| 22 | 268 | 284 | 170 | 268 | 284 | 167 |

| 24 | 319 | 338 | 202 | 319 | 338 | 199 |

| 26 | 374 | 397 | 237 | 375 | 397 | 233 |

| 28 | 434 | 460 | 275 | 435 | 461 | 270 |

| 32 | 567 | 601 | 359 | 568 | 602 | 353 |

Steel Chemistry

A combination of steel grades is used and heat treatment processes to manufacture soft, medium and hard tensile grades. The table below is indicative only of steel chemistries used.

Tensile Grade | % Carbon | % Phosphorus | % Manganese | % Silicon | % Sulphur |

Standard | 0.45~0.50 | 0.032 | 0.5 ~1.00 | 0.10~0.34 | 0.041 |

High | 0.59~0.63 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

Extra-High | 0.65~0.83 | 0.035 | 0.5 ~1.10 | 0.10~0.35 | 0.045 |

Quality Control:

We use total quality control system. Every pieces of the raw material; semi-finished products and finished products are tested and recorded in file. The tracking record is used from final products to the very first beginning raw material steel factories.

Third Part like SGS is available for test control before shipment

Packing:

1) All the products are packed with seaworthy packing.

2) Customer’s special requirement for packing can be satisfied.

3) Air freight; sea freight and truck freight are all available.

FAQ

Q: Manufacturer or Trader?

A: We are manufacturer in wire industry for more than 20 years.

Q: Producing Capacity?

A: The producing capacity totally is 9, 000 tons per month. The producing capacity of this product is 1,500 tons per month.

Q: Main Market?

A: Our main market is foreign customers. 80% of the products are for exporting. The main countries are Japan, South Korea, South Asian area, Europe, America, Canada, and South America etc.

Q: What information should I provide when inquiring?

A: The diameter before pvc coating; after pvc coating, the requirement of the core wire like zinc coating, tensile strength, packing, colour

Q: What is the MOQ?

A: For quality checking, we accept small quantity order like one coil. For normal cooperation, we prefer FCL container quantity to ensure the safety of goods in transportation.

Q: What is the payment term?

A: T/T; L/C; D/P etc

Q: Free sample available?

A: Yes. Free sample within 2kg is available

Q: Third Party Inspection available?

A: Yes, available. The charges are on the buyer.